AI-Powered Precision

Advanced machine learning algorithms ensure perfect weld quality and consistency in underwater environments.

The Future of Underwater Welding Technology - AI-Powered Marine Construction

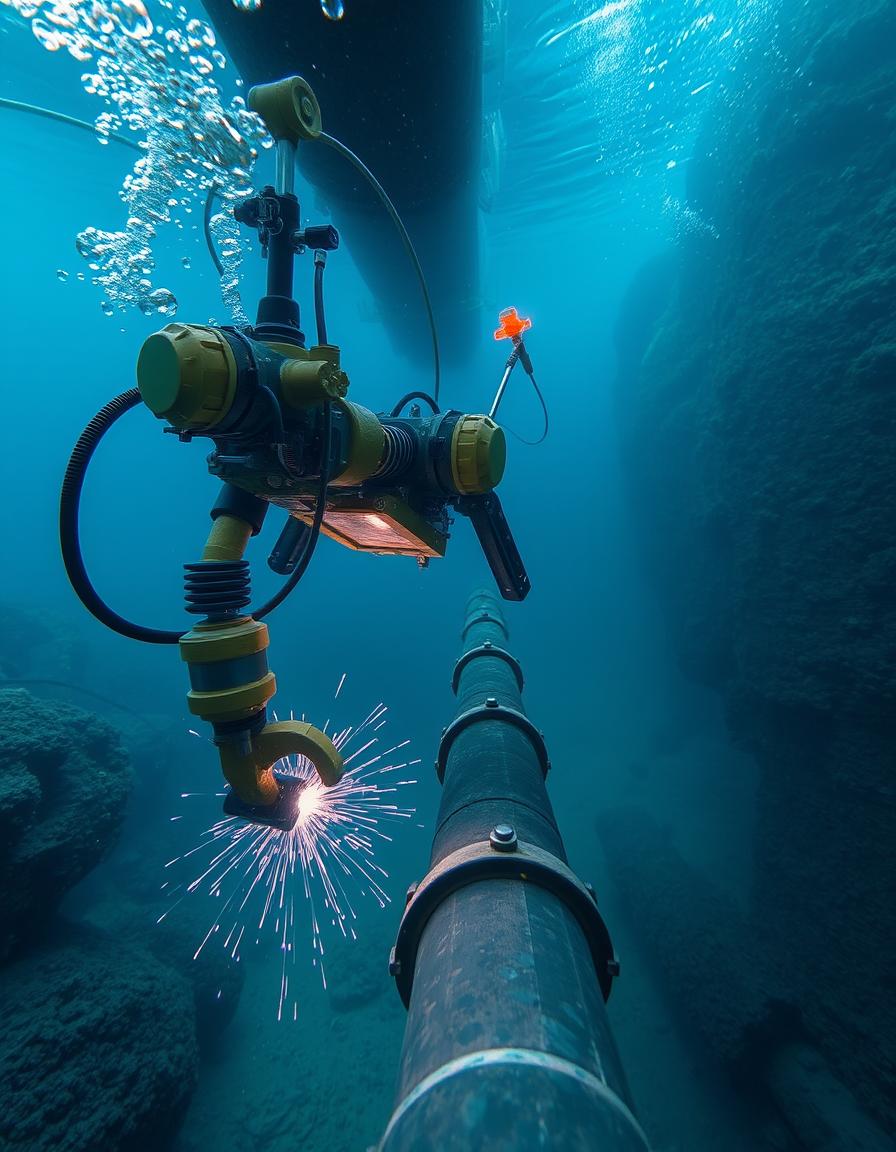

Current underwater welding operations require highly skilled divers working in hazardous conditions, with limited precision and high costs. REXWELD AI revolutionizes this process with autonomous, AI-powered underwater welding technology that delivers superior results safely and efficiently.

REXWELD AI combines advanced robotics, artificial intelligence, and marine engineering to perform underwater welding operations with unprecedented precision, safety, and quality control in marine environments.

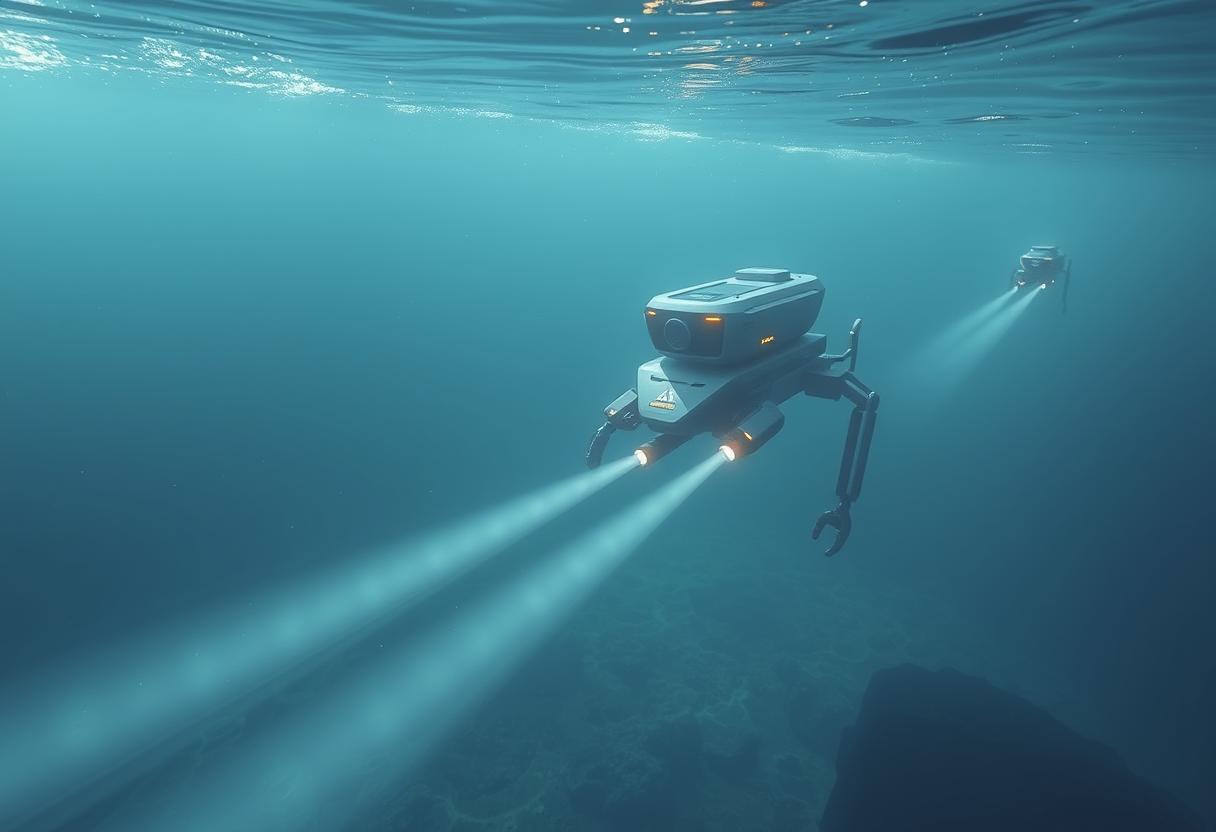

Advanced AI-powered underwater welding technology capabilities that transform marine construction and infrastructure maintenance.

Advanced machine learning algorithms ensure perfect weld quality and consistency in underwater environments.

Continuous quality control and safety monitoring throughout the underwater welding process.

Fully automated underwater welding operations reducing human risk and increasing efficiency.

Significantly reduces operational costs compared to traditional underwater welding methods.

Advanced technical capabilities and specifications of REXWELD AI underwater welding technology.

Industries and use cases where REXWELD AI transforms underwater welding operations.

Pipeline repairs, platform maintenance, and underwater infrastructure welding for offshore energy operations.

Hull repairs, propeller welding, and underwater vessel maintenance without dry-docking requirements.

Bridge construction, port infrastructure, and underwater structural welding for marine projects.

Pipeline installation, repair, and maintenance for underwater utility and transportation systems.

Offshore wind farm installation, maintenance, and underwater cable welding for renewable energy projects.

Military vessel repairs, submarine maintenance, and underwater defense infrastructure welding.

Advantages and benefits of implementing AI-powered underwater welding technology in your marine operations.

Eliminates human risk in hazardous underwater welding environments while maintaining superior quality standards.

AI-powered precision ensures consistent, high-quality welds that exceed traditional underwater welding standards.

Significant reduction in operational costs compared to traditional underwater welding methods and techniques.

24/7 operation capability with remote monitoring and control for maximum operational efficiency.